How to Measure a Roller

How to Measure a Roller

You may need to replace a roller for your conveyor system and Roll Ezy can manufacture and replace bespoke rollers for your system. It is very important that the measurements supplied are correct as our quotation for the work and also the actual rollers themselves will be based upon the measurements provided (unless you can provide one of the actual rollers being replaced).

Below are photographs to help guide you on how to measure a roller and what measurements are required. Once you can provide these we will contact you to ask a few further questions and we can then provide you with an accurate quotation.

We can manufacture other steel sprockets made to order, but we require a detailed drawing on enquiry and these products will have a longer lead time.

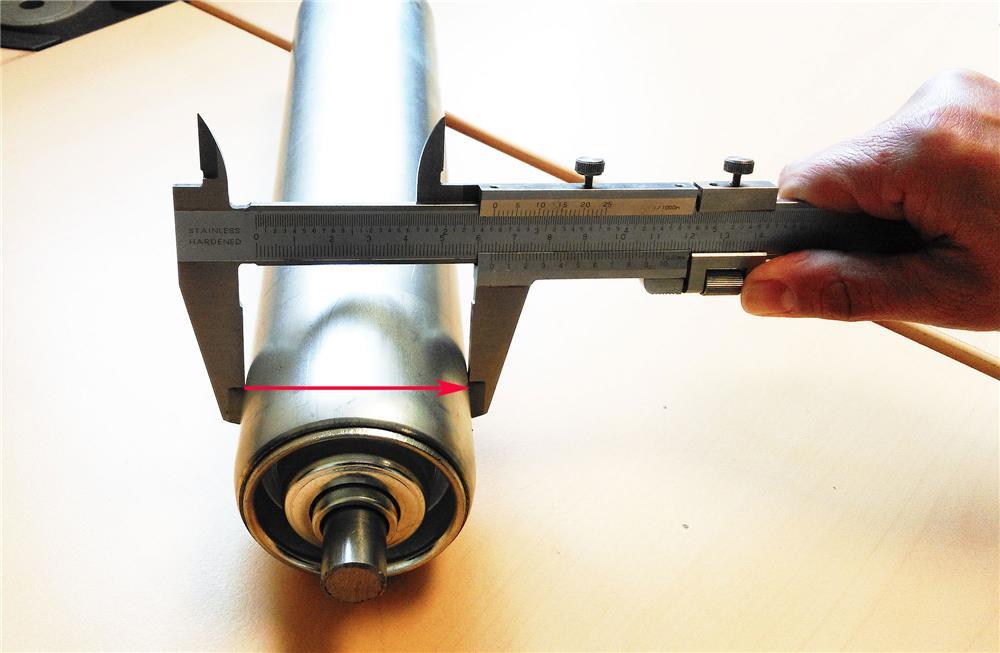

Step 1: Tube Diameter

This is the diameter or width of the tube and can be measured using a vernier or a set of rulers.

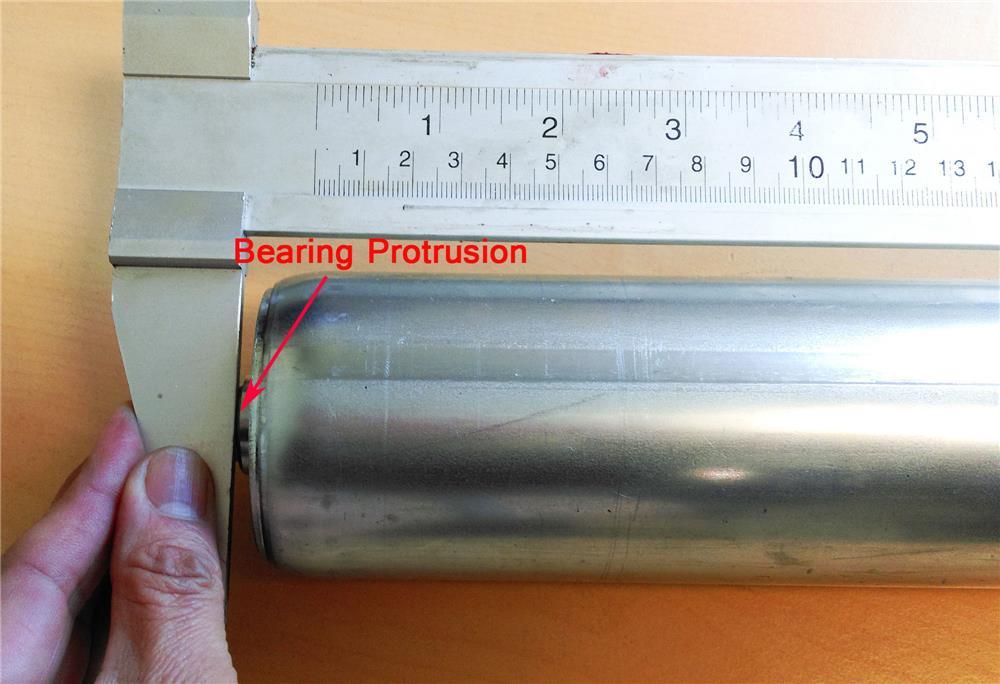

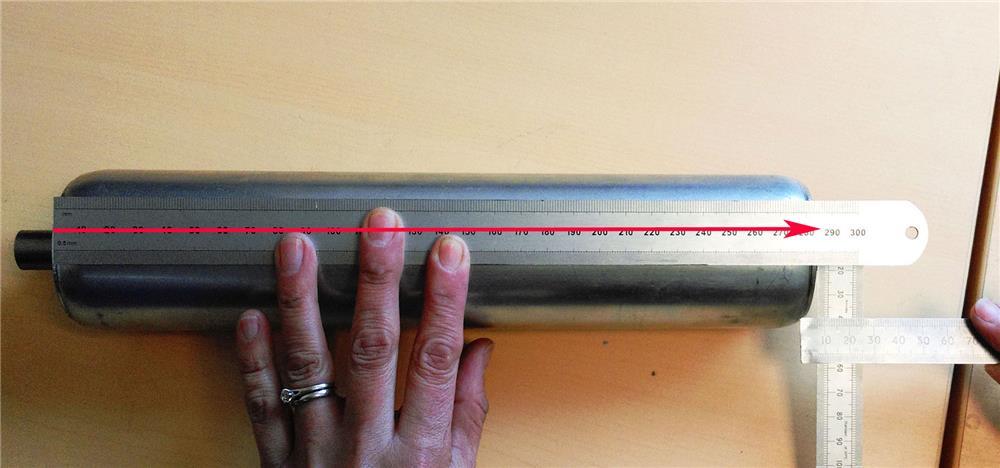

Step 2: Overbearing

This is the length of the tube plus the bearing protrusion at each end of the tube.

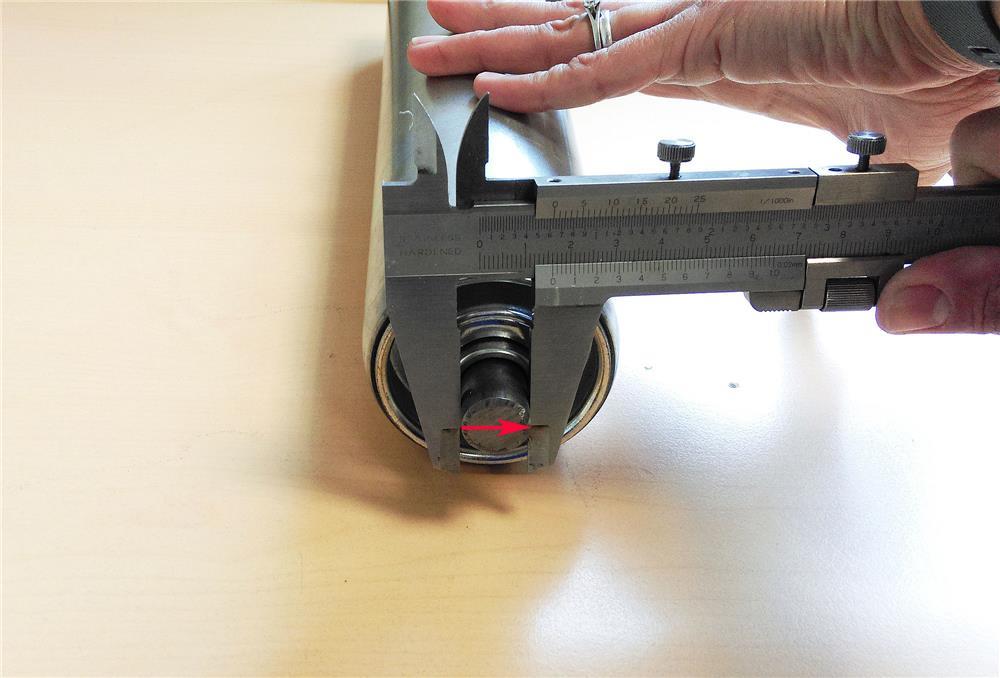

Step 3: Shaft Diameter

This is the diameter or width of the shaft and this again can be measured with a vernier or ruler.